| brand | Kehai | Yes / No support for processing | yes | Specifications | 4600mm |

| Compressed medium | Natural Gas | admission pressure | ordinary pressure | Discharge pressure | 10kg |

| rate of flow | 83cubic / min | temperature | 25 | Cooling-down method | air cooling |

| navar | PLC | dimensions | 4600*2400*3200mm | lubricating system | forced lubricgtion |

| power of motor | 110KW | Available for sale | globally | Model | KHDY010 |

Kehai

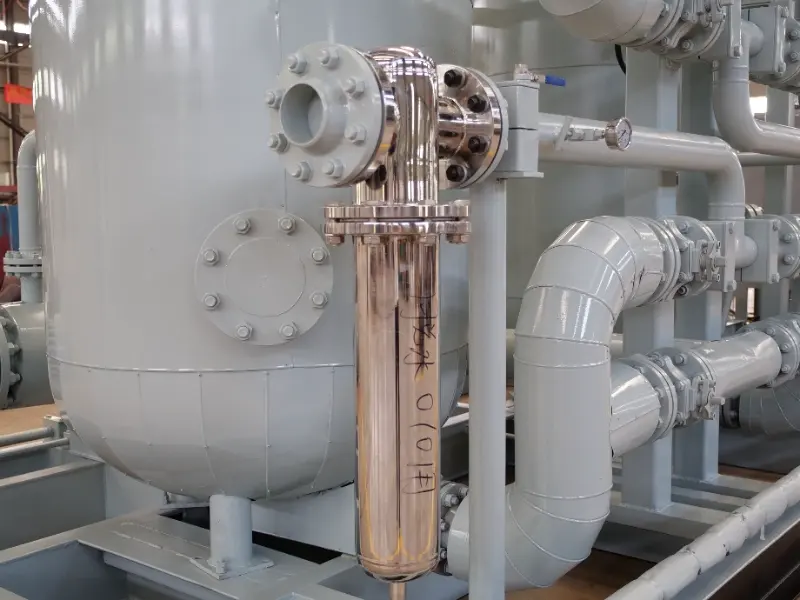

KHDY010 Natural gas Dewatering Device

Customize products according to user’s working conditions parameters.

The natural gas dryers produced by our company are widely used in shale gas CBM and CNG industries. The dehydration of shale gas and coalbed methane is very different from that of CNG, because compared with CNG, the water of shale gas and coalbed methane belongs to saturated water and contains more water. However, CNG is unsaturated water with less water content, and the temperament components of shale gas and coalbed methane are complex compared with CNG. The shale gas drying system produced by our company is widely used in Sinopec's Anzhai, Daniudi, Wanxian and other shale gas Wells.

1, the company introduced advanced simulation software ASPEN, according to different component pressure and temperature accurately calculate the water content of the gas, the equipment better meet the actual use requirements. At present, most manufacturers in the industry still use the chart method to determine the water content of natural gas, which is very different from the actual water content. The phenomenon of unclean dehydration or short adsorption time often occurs.

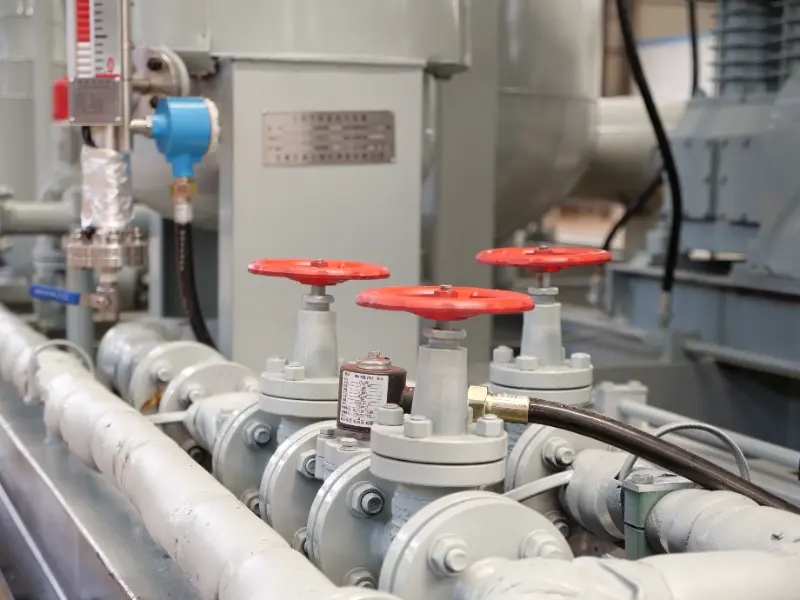

2, the use of isobaric closed cycle regeneration process. The whole system is implemented to discharge. The unit runs smoothly, reliably and with low noise.

3, good regeneration effect, more energy saving, more environmentally friendly.

4, the use of advanced 4A molecular sieve, such as the United States UOP, zeolite, etc.

product description

Service Process

-

01

Project communication

-

02

Exchange of technical parameters

-

03

Develop a design plan

-

04

Sign a contract

-

05

Compressor manufacturing

-

06

Packaging and transportation

-

07

Installation, operation and debugging

-

08

Customer training

-

09

Customer acceptance